Micro-LEDs represent one of the most exciting frontiers in display technology. With chip dimensions below 50µm, they promise unmatched brightness, power efficiency, and lifetime compared to OLED and LCD. But these advantages come with one of the most complex challenges in modern manufacturing: handling and precisely assembling millions of microscopic dies with high throughput and near-perfect yield.

The Manufacturing Challenge

Producing a 4K display requires ~25 million individual micro-LEDs, each of which must be transferred from a donor wafer to a TFT backplane with sub-micron accuracy. Even a 0.01% defect rate results in hundreds of defective dies per panel. Manufacturers therefore need not only high-speed transfer technologies but also reliable repair capabilities for defective pixels.

Three mass-transfer approaches have emerged:

- Stamp transfer – a mechanical process that shuttles thousands of micro-LEDs simultaneously.

- Laser-based methods – including Laser Lift-Off (LLO) and Laser-Induced Forward Transfer (LIFT), which combine high accuracy with the ability to change pitch between donor and receiver substrates.

- Self-assembly – a fluidic process where dies settle into defined sites, guided by mechanical or electromagnetic forces.

While stamp transfer remains common, laser-based approaches are increasingly favored due to their higher precision and scalability.

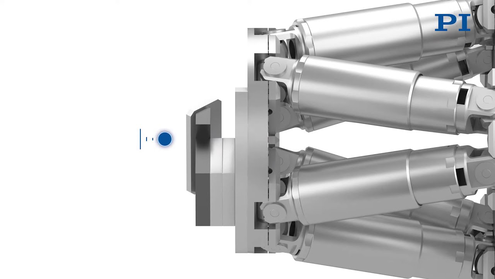

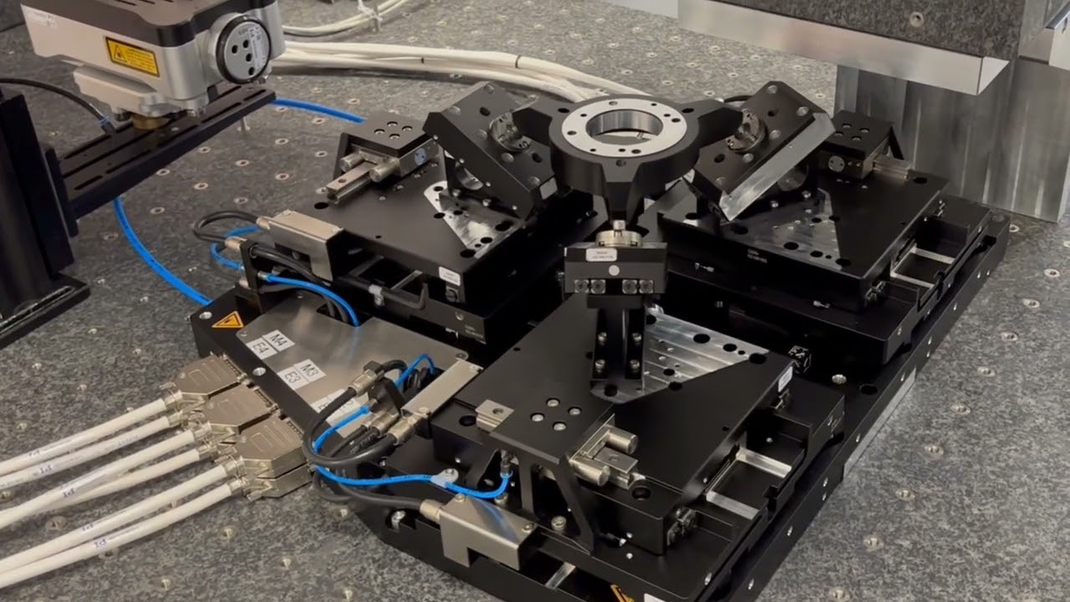

Hexapods—six-axis parallel-kinematic platforms—play a central role in enabling these processes. Unlike stacked stages, a hexapod can simultaneously control all six degrees of freedom (X, Y, Z, pitch, roll, and yaw) with high stiffness and compact footprint. This makes them uniquely suited for micro-LED transfer, alignment, and repair tasks.

Mass Transfer and Laser Processes

During LLO and LIFT operations, wafers must be aligned with parallelism tolerances of just a few microns across a 200mm or larger surface. Hexapods excel here:

- Their high stiffness and resolution allow for high Z-axis precision with excellent tip/tilt correction if needed, rotating around a user defined pivot point. This allows for the donor and receiver wafers to remain perfectly parallel.

- Distance sensors can be used in real-time feedback loops to allow the hexapod to maintain separation distances in the low micrometer range.

- Custom alignment algorithms can further optimize wafer parallelism during dynamic processing.

Defect Repair

Even at 99.999% yield, a 4M-die display requires replacement of ~40 defective LEDs. Here, hexapods provide the precision alignment needed for single-die pick-and-place operations, ensuring the defective chip is removed and replaced with micron-level accuracy.

Welding and Bonding

Following transfer, thermal or laser welding is required to create electrical connection between TFT substrate and LED dies. This process applies forces of 20–30N, demanding a rigid and stable motion platform. Hexapods provide both stiffness and repeatability to minimize drift during bonding.

Advantages of Hexapods over Conventional Multi-Axis Stage Stacks

Compared to serial kinematic stage stacks, hexapods offer:

- Higher stiffness with lower moving mass

- Improved repeatability in angular motions (tip/tilt)

- Compact design with easier integration

- Software-defined virtual pivot points for flexible alignment around optically significant features

These characteristics make them ideal for both R&D environments and scalable industrial equipment.

Conclusion

Hexapods have been used in many optical alignment processes, from miniscule fiber array components to mirror segments of the largest telescopes in the world. Their unique capabilities make them compatible with micro-LED production—they are enablers of the technology’s scalability. From wafer-to-wafer transfer using LLO/LIFT, to single-die defect repair, to the final bonding steps, hexapods deliver the six-degree-of-freedom precision, stiffness, and repeatability that next-generation display manufacturing demands.

As micro-LEDs move toward mass adoption in smartwatches, automotive displays, AR/VR headsets, and large-format TVs, hexapods will be essential building blocks in the manufacturing equipment that makes this leap possible.

Blog Categories

- Aero-Space

- Air Bearing Stages, Components, Systems

- Astronomy

- Automation, Nano-Automation

- Beamline Instrumentation

- Bio-Medical

- Hexapods

- Imaging & Microscopy

- Laser Machining, Processing

- Linear Actuators

- Linear Motor, Positioning System

- Metrology

- Microscopy

- Motorized Precision Positioners

- Multi-Axis Motion

- Nanopositioning

- Photonics

- Piezo Actuators, Motors

- Piezo Mechanics

- Piezo Transducers / Sensors

- Precision Machining

- Semicon

- Software Tools

- UHV Positioning Stage

- Voice Coil Linear Actuator

- X-Ray Spectroscopy